Food irradiation is the physical treatment of food with high-energy ionising radiation for the purpose of prolonging shelf life and prevent food-borne diseases in meat, poultry and seafood. Irradiation achieves this by destroying micro-organisms, viruses, bacteria or insects; preventing germination and sprouting of potatoes, onions and garlic and slowing down the ripening and ageing of fruit and vegetables.

Irradiation can reduce the risk of food poisoning, control food spoilage and extend the shelf-life of foods without detriment to health and with minimal effect on nutritional or sensory quality. This view has been endorsed by international bodies such as the World Health Organisation (WHO), the Food and Agricultural Organisation (FAO) and Codex Alimentarius.

Irradiated food should not be confused with the possible radioactive contamination of foods following nuclear incidents. Irradiated food exposed to ionising radiation sources does not become radioactive itself. The amount of energy that is used in effective food irradiation is low compared to cooking. Multiple safety assessments by governmental authorities have confirmed that irradiated food is safe to consume.

Food irradiation, when carried out under conditions of Good Manufacturing Practice (GMP), is an effective and efficient food processing method, is judged to be safe based on extensive available scientific evidence. Irradiation should not be used as a substitute for good hygienic and good manufacturing practices or good agricultural practices. For the irradiation of any food, the minimum absorbed dose should be sufficient to achieve the intended technological purpose and the maximum absorbed dose should be less than that which would compromise consumer safety, wholesomeness or would adversely affect structural integrity, functional properties, or sensory attributes.

IntroductionMany processing methods have been developed to help prevent food spoilage and improve safety. The traditional methods of preservation, such as drying, smoking and salting have been supplemented over time by pasteurisation (by heat), canning (commercial sterilisation by heat), refrigeration, freezing, the addition of chemical preservatives and use of irradiation.

Irradiation of food is not new. Interest in treatment of food with ionising radiation was shown in Germany in 1896 (Stewart, 2004(a)) and food irradiation has been applied since the early 1920s. In the 1950/60s the US Army Natick Soldier Center (NATICK) experimented with both low dose and high dose irradiation for military rations, whilst at the same time, the United Kingdom (UK) authorities Low Temperature Research Station programme concentrated on low dose pasteurisation (Hannan, 1955). Irradiation is extensively used in the medical field for sterilising instruments, dressings, etc. and for sterilisation of packaging used for a range of consumer products including medicines, cosmetics and food.

Essential ReadingCodex Alimentarius General Standard for Irradiated Foods CXS 106-1983, Rev.1-2003 Available online: https://www.fao.org/fao-who-codexalimentarius/codex-texts/list-standards.

European Food Safety Authority; Statement summarising the Conclusions and Recommendations from the Opinions on the safety of Irradiation of Food adopted by the BIOHAZ and CEF Panels. EFSA Journal 2011; 9(4): 2107. [155 pp.] doi:10.2903/j.efsa.2011. 2107. Available online: www.efsa.europa.eu/efsajournal

History and future of food irradiation, József Farkas, Csilla Mohácsi-Farkas, Trends in Food Science & Technology, Volume 22, Issues 2–3, 2011, Pages 121-126, ISSN 0924-2244, https://doi.org/10.1016/j.tifs.2010.04.002 .

Subject Interest Area:

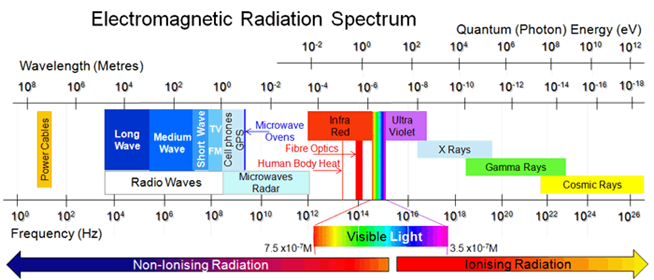

Irradiation refers to the process by which an object is deliberately exposed to a certain type of radiant energy known as ionising radiation [1] . Radiant energy comes from a variety of sources producing radiation with different wavelengths and degrees of power. The degree of radiation penetration into materials is dependent on its wavelength. Light (including ultraviolet, visible and infrared light), radio waves, and microwaves are all types of non-ionising radiation. Ionising radiation on the other hand carries more energy that non-ionising radiation and can produce charged particles (ions) in matter, hence the name. When ionising radiation penetrates a material; this type of radiant energy is absorbed in part or completely by the treated material. The absorbed radiant energy causes excitation, ionisation and chemical alteration of the treated material components. Once the irradiation treatment stops, the material quickly loses this absorbed energy in the same way that cooked food quickly cools down.

Free radicals formed upon irradiation with ionising radiation are highly reactive and very short-lived, so short-lived that they cannot be detected in water-containing food almost immediately after it has been irradiated. In all but very dry matter, such as bone or shell, small amounts of substances are formed upon treatment with ionising radiation, some of which are highly active but transient free radicals, others of which are useful as markers which can be used to determine whether or not the food has been irradiated. It is the action of the transient free radicals, which accounts for much of the effects (killing pathogenic bacteria, extending shelf-life etc.) of irradiating food.

Ionising radiation is therefore effective for sterilisation and reducing viable presence of pathogenic microorganisms, whether used in irradiation of medical instruments, packaging or foods, because high-speed electrons, gamma rays and X-rays, and the free radicals they produce, denature DNA (deoxyribonucleic acid) and RNA (ribonucleic acid). Disruption of the weak hydrogen bonds between nucleotides prevents DNA and RNA replication and causes cell death while exerting minimal effects on non-living tissue. In much the same way, ionising radiation can slow down cell-based processes such as ripening of fruit, which would lead to premature decay or sprouting of vegetables.

The unit of ionising radiation absorbed dose is a Gray (Gy). One Gray corresponds to the absorption of one joule of energy in a mass of one kilogram (1Gy = 1J/kg). The Gray has superseded the older unit, the rad (1Gy = 100 rad). The length of time the material is exposed to the ionising energy coupled with the strength of the source determine the irradiation dose, measured in Gray (Gy), or kiloGray (kGy).

Food IrradiationFood irradiation is the exposing food to a carefully controlled dose of ionising radiation in order to, among other things, control foodborne pathogens, reduce microbial load and insect infestation, inhibit the germination of root crops, and extend the durable life of perishable produce. Irradiated food is not radioactive and should be safe to consume, providing the irradiation treatment is performed such that the food never comes into contact with the ionising radiation source, performed under controlled conditions using an approved source and at a licensed approved irradiation premises.

A fundamental principle in the use of radiation processing is that irradiation should never be used as a substitute for good manufacturing practices (GMP) in the control of food safety and quality. It is unacceptable to attempt to irradiate an unfit or contaminated foodstuff or out of date food to render it fit to consume. Food irradiation can however play a significant role where GMP and prerequisite controls are not sufficiently capable of delivering the level of microbiological quality required. It can offer a tool for food decontamination from microbial loading and for controlling pest infestation of foods and of plant materials more broadly. The increased globalisation of trade has increased the likelihood of invasive species being introduced to new countries and climate change has increased the likelihood that invasive species will survive in these new environments. Irradiation can prevent the reproduction of adult insects and their larvae and can as such be an effective tool to address plant health risks. Irradiation is however not suitable for on the spot treatments when infestations are discovered, due to the specific infrastructure and packaging required to carry out irradiation.

Currently, radiation sterilisation of agricultural and food products is carried out in more than 60 countries. According to the UN FAO, more than 200,000 tons of irradiated products are annually produced only in Europe. For many types of products, the optimal modes of radiation sterilisation were determined, long-term studies of their suitability and harmlessness for use were carried out, and adequate radiation equipment was created. Decontamination of spices, herbs and condiments remains the single largest application of irradiation. In recent years the market for irradiated fresh and processed meat has become firmly established in several countries including China and the USA. At least 10 countries have recently established bilateral agreements for trade in irradiated fresh fruits and vegetables using phytosanitary irradiation. Irradiated fresh produce volumes now exceed 20,000t per year (Ferreria et al 2017).

Safety of Irradiated FoodMore than 100 years of research have gone into the understanding of the safe and effective use of irradiation as a food safety method, more than any other technology used in the food industry today, even canning (Scott Smith and Pillai, 2004). The safety and efficacy of the technology has been repeatedly considered and judged acceptable on available evidence. This has resulted in international bodies including the World Health Organisation (WHO), the United Nations Food and Agriculture Organisation (FAO), the International Atomic Energy Agency (IAEA) and Codex Alimentarius commending food irradiation as a process supporting food hygiene and food safety.

A maximum overall average dose of 10 kGy was considered adequate for the majority of food applications. Over 50 countries have given approval for the irradiation of over 60 foods and food products on either a conditional or unconditional basis. Research carried out worldwide has shown that irradiation of food is a safe and effective way to kill bacteria in foods and extend its shelf life. Food irradiation has been examined thoroughly by joint committees of the WHO, FAO, by the European Community Scientific Committee for Food, the United States Food and Drug Administration (FDA) and by a House of Lords committee in the UK. In 2011, the European Food Safety Authority (EFSA) reviewed the evidence and reasserted the opinion that food irradiation is safe (EFSA, 2011). They concluded:

The recent European Union (EU) evaluation of the EU legal framework on food irradiation (EC, 2021), restates that food irradiation is an established food decontamination technique and when integrated into an overall food safety management program that includes Good Agricultural, Manufacturing and Hygienic Practices and HACCP, and depending on the dose applied, food irradiation can contribute to improved consumer safety by reducing food-borne pathogens. Concerns raised by consumer associations and the European Parliament that food irradiation may be misused by food business operators to mask poor hygiene in production processes, were addressed. The EU confirmed that such practice would be in contradiction with the food hygiene regulations.

Concerns regarding the toxicity of the 2-alkylcyclobutanone (2-ACBs) group of radiolytic compounds have been identified. New studies carried out confirm that the ingestion of 2-ACBs through irradiated foods is unlikely to affect the human health but suggest that the determination of chronic toxicity by long-term exposure to low concentrations of 2-ACBs has to be evaluated more clearly to determine if these compounds are safe to human. Considering that only a very limited quantity of food is irradiated in Europe currently, the current view is that there is not an immediate cause for concern.

A concern was also raised by one national competent authority, in the 2021 EU evaluation, about possible migration of elements from packaging and into food in the context of food irradiation. It is described in the scientific literature that for pre-packaged foods undergoing irradiation, packaging made from polymers are susceptible to radiation effects. The extent of these effects differs depending on the polymer. This is not a new issue, and packaging materials used for foods undergoing irradiation must be suitable for the purpose. As new packaging materials are developed, they should be tested before use in the irradiation process.

Foods sterilised by high dose irradiation (>25 kGy), cold sterilisation as opposed to thermal sterilisation (canning), have been consumed by astronauts in the NASA space shuttle programme because of their superior quality and variety, compared to foods treated by other preservation technologies. There is a small but increasing demand for sterile products for immunocompromised patients as well as for niche markets, such as the military, campers or disaster victims where a long shelf life at ambient temperatures is required. High dose sterile foods may be prepared under medical supervision for immunocompromised patients without labelling. A research programme on Irradiated Foods for Immuno-compromised Patients was coordinated by the IAEA (IAEA, 2010).

Quality of Irradiated FoodIrradiation is very effective against living organisms which contain DNA and/or RNA but does not cause any significant loss of macronutrients. Proteins, fats and carbohydrates undergo little change in nutritional value during irradiation even with doses over 10 kGy, though there may be sensory changes. Similarly, the essential amino acids, essential fatty acids, minerals and trace elements are also unaffected. There can be a decrease in certain vitamins (particularly thiamin), but these are of the same order of magnitude as occurs in other manufacturing processes such as drying or canning (thermal sterilisation) (WHO, 1994; FAO/IAEA/WHO, 1999; EFSA, 2011). In some cases, vitamin levels can be found to increase. Niacin content of bread from irradiated flour was found to be 17% more than the non-irradiated control flour (Diehl, 1991) and an increase in the niacin content (24%) and riboflavin content (15%) in pork chops after irradiation was reported in another study (Fox et al, 1989).

The irradiation process is not suitable for all products. Foods with high fat contents, such as fatty fish and some dairy products, can develop off-odours and tastes due to the acceleration of rancidity, even at relatively low doses. Loss of firmness can occur with some fruits and vegetables. Foods with a high protein content, such as meat and poultry, can suffer from changes in flavour and odour after irradiation at ambient temperatures but these changes can be reduced by irradiating at chill temperatures and minimised by irradiating at frozen temperatures. For fresh ground beef with a high fat content and for fatty pork products, the maximum dose should not exceed 2.5 kGy to prevent rancidity. Liquid and dry eggs can tolerate doses in excess of 3 kGy, but for shell eggs a 2 kGy dose can cause deterioration of the yolk sac membrane. Milk develops an off-flavour at relatively low doses, but various cheeses show good tolerance at doses up to 3 kGy (Diehl, J.F., 1983). All these changes are minimised by irradiating at chill or frozen temperatures, and, in addition, many changes can be minimised by careful choice of suitable packaging systems coupled with controlled gas atmospheres.

Food Irradiation ApplicationsWith respect to dose, populations of pathogenic and spoilage microorganisms in food products vary significantly in their radiosensitivity. For example, the lethal dose for mould fungi Penicillium expansum is 100–200 kGy, and for Pullularia pullulans, it is 2000 kGy. For solving this problem, the IAEA special commission proposed several different modes for radiation treatment for sterilisation: radicidation (4 - 6 kGy), radurisation (6 - 10 kGy), and radappertisation (10 - 50 kGy) (Obodovskiy, 2019).

Radurisation , from the Latin ‘radiare’ (radiate) and ‘durare’ (prolong), is a radiation treatment of food products for increasing the duration of storage, in doses, leading to limited suppression of certain pathogenic for humans’ microorganisms. For example, treatment of potatoes and onions with 0.05 - 0.15 kGy to inhibit germination; treatment of grains, fruits with 0.15 - 0.50 kGy for pest control; treatment of fruits and vegetables with 0.5 - 1.0 kGy to slow maturation, treatment of strawberries and vegetables with 5 - 3.0 kGy to extend the shelf life, and treatment of fresh and frozen chicken meat, shrimps, frog's feet with 2.0 - 5.0 kGy for the destruction of pathogenic parasites and microorganisms.

Radicidation from the Latin ‘radiare’ (radiate) and ‘ocsidere’ (kill), is a radiation treatment for the purpose of selective suppression of microorganisms of any type, e.g. Salmonella, Trichinella. For example, treatment of food products with 2 - 10 kGy to improve the technological properties of a number of foods.

Radappertisation, by the name of Nicolas Appert, the inventor of thermal sterilisation method of food products, is carried out for industrial sterilisation of food products for complete destruction of microorganisms, as it occurs in the thermal sterilisation in canned food manufacturing. For example, treatment of food additives and some ingredients, e.g. spices with 10 – 50 kGy for disinfection and treatment of meat, meat products, dietetic products for sick people with 30 - 50 kGy for sterilisation.

The absorbed doses permitted for food irradiation are usually defined in regulatory requirements where the ionising radiation sources, irradiation conditions and doses for food irradiation are prescribed for specific types of foods and purposes. Doses of irradiation that have been approved vary from 0.05 kGy, to inhibit sprouting in white potatoes, to 30 kGy, to sterilise herbs and spices.

Three principal types of radiation source can be used in food irradiation according to the Codex Alimentarius General Standard 106 (Codex, 2003):

(a) gamma radiation from radionuclides such as 60 Co or 137 Cs

(b) machine sources of electron beams with energies up to 10 MeV

(c) machine sources of bremsstrahlung (X-rays) with electron energies up to 5 MeV.

The choice of irradiation method and the dose applied will depend on the material needing to be treated and the intended purpose for treatment. The effectiveness of processing of food by ionising radiation depends on proper delivery of absorbed dose and its reliable measurement. It is important that the dosimetry techniques used for dose determination are carried out accurately and that the process is monitored.

Food irradiation is carried out in specific containment areas applying the necessary shielding to prevent the escape of ionising radiation and to avoid exposure of personnel. In automated irradiation facilities, conveyors or other carrier systems move the products to be irradiated at a predetermined speed or rate to deliver the necessary dosage. At no time during the irradiation process does the food come into contact with the radiation source. By using gamma rays, X-rays up to 5 MeV or electron beams up to 10 MeV, none of these kinds of ionising radiation have energy levels sufficient to induce radioactivity in the irradiated food.

Gamma rays and X-rays can penetrate food to a depth of about 1 metre; whereas an electron beam can only penetrate foods to a depth of about 3cm. Thus, to treat the surface or a thin layer of a food, one would usually choose to use an electron beam. These are easy to produce electronically but they do not have deep penetrating power. For situations where only shallow penetration is needed and where rapid conveyor speeds can be used, high power electron beams may provide a higher output at lower cost per unit of product when large amounts of product are involved. To treat a bulky product such as an entire sack of spices, one would choose gamma rays or X-rays. Irradiation using a gamma ray source is possible from two sides either by turning the process load or by irradiation from two sides of a plaque source, often used to increase the dose uniformity in the process load (Olivieira, et al., 2000; Saylor & Jordan, 2000).

Food once irradiated, can be prone to re-contamination unless appropriately packed. Pre-packaging is an integral part of the process when irradiation is intended to control microbiological spoilage or insect infestation. The packaging provides the technical function of protecting the food product from external conditions such as prevention of moisture uptake or loss, maintenance of an atmosphere other than air, protection from mechanical damage and from contamination from physical, chemical and microbial hazards. Since packaging materials are therefore also exposed to irradiation during the treatment, these materials must also satisfy additional requirements such as resistance to irradiation with respect to its functional properties and as a suitable food contact material. It therefore should not transmit toxic substances into food nor impart any off odour to the products. It is possible that irradiation might either affect barrier properties or that radiolytic products formed in the packaging might be absorbed into the product. Consideration should also be given to the suitability of components such as absorbent pads, adhesives and printing inks, especially in minimising the risk of taint from low levels of radiolytic products. Increasingly, packaging materials for use in aseptic processing lines in the food, pharmaceutical and cosmetic industry are now being sterilised by ionising radiation. The evaluation of the suitability of new packaging materials for irradiation either when used to pack foods for irradiation or for direct irradiation for sterilisation of packaging priori to use is described in Komolprasert (2007).

A number of applications for food irradiation have been identified, aimed at improving microbiological safety and reducing food spoilage. Examples of application areas include:

Insect contamination/infestation - low dose (less than 1 kGy) irradiation for insect control (for instance in grain and grain products) where a dose of 150-700Gy is sufficient.

Poultry and poultry products, including mechanically recovered meat - to reduce numbers of Salmonella, Campylobacter and other food poisoning bacteria. Doses of up to 3 kGy (fresh) and up to 7 kGy (frozen) have been recommended. In 2012, the Food and Drink Administration (FDA) extended the maximum dosage for poultry in the USA to 4.5 kGy.

Red meats, including particularly comminuted meat such as used in hamburgers - to reduce numbers of E.coli O157:H7 and other food poisoning bacteria. Doses of up to 4.5 kGy (fresh) and up to 7 kGy (frozen) have been recommended. The irradiation of meat in the USA was extended by the FDA in 2012 to cover unrefrigerated meat.

Frogs’ legs, especially in Belgium, France, The Netherlands and Finland - to reduce numbers of food poisoning bacteria

Dried herbs and spices - to reduce overall levels of contaminating pathogenic microorganisms generally and to reduce or eliminate food poisoning bacteria in particular. Doses up to 10 kGy have been recommended. Herbs and spices are the food materials most commonly irradiated. These raw agricultural products, grown and harvested by traditional methods are only processed by mild drying which does not reduce the level of microbes present. Alternative methods to reduce microbial numbers have used chemicals, such as ethylene oxide and methyl bromide that are now considered dangerous to humans and/or the environment. This has led to a large trade in steam flash pasteurised spices, but which can result in flavour losses.

Certain fruits and vegetables in order to reduce the numbers of microorganisms, particularly those that cause spoilage - doses of up to 2 kGy have been recommended. Irradiation has been shown to have minimal effect on flavour, aroma and colour but can have an adverse effect on texture (Komolprasert,V, 2002). Irradiation in combination with modified atmosphere packaging (MAP) exerts a useful synergistic effect (Grant, I.R. and Patterson, M.F., 1991) although this combination processing is not allowed in some countries. Irradiation of onions, garlic, mung beans and tamarind is commercially viable in Thailand. Irradiation is also useful in combating rice weevil (Sirohilus oryzae) and lesser grain borer (Rhyzopertha dominice). It is particularly effective against internal feeders. Only a few species are internal feeders, but larvae and pre-emergent pupae present the greatest challenge.

Leafy vegetables, especially salad leaves - the USA approved the use of irradiation of spinach and iceberg lettuce in 2008 on grounds of safety and shelf life extension. This followed several cases of food poisoning attributed to E.coli contamination, including fatalities.

Bulbs and tubers, such as potatoes and onions - for various purposes. Doses of less than 1kGy have been recommended. Potatoes have been irradiated in Japan for over 26 years to prevent sprouting (IAEA 1991), and sweet potatoes are irradiated in Hawaii to control insect infestation (Follett and Weinert, 2012).

Sterilise foods with longer shelf life or for specific purposes, such as ready meals, for special medical diets, emergency or space diets - these foods are irradiated by doses of 45 kGy to render the foods microbiologically sterile. The irradiation is carried out under frozen conditions to minimise adverse sensory effects. The foods can be subsequently distributed unrefrigerated. Shelf-stable meat dishes have been prepared in South Africa since 1989 for both military and non-military uses (WHO, 1999), but has since been discontinued on cost grounds (Amanda Minnaar, personal communication).